Core DC Magnetron spunding depositione ratio mendacium in ingeniosi combinatione DC virtutis copia et magneticam agri. In vacuo environment, in DC potentia copia est summus voltage electrica agro inter scopum et subiectum. Cum electrica agri vires est magna satis, inerti Gas moleculis intrantes vacuum cubiculum sunt ionized ad formam Pure. Positivum ions in his Plasmas accelerantur sub actione electrica agro ledo superficie scopum ad celeritate.

Per collisione processus, atomis vel moleculis super superficiem in scopum sunt sputyrum sunt, quia adipiscuntur satis industria ad formam spuctletus particulas. Hae particulas fugere in vacuo et eventually depositum super superficiem subiecti ad formare requiritur amet. Valet notantes quod processus non solum simplex corporalis collisione, sed etiam comitatus per universa corporalis et eget profectae, ut ion neutralization, electronic capere et re-emissionem, etc.

Simple DC spundering ut causa problems ut subiectum overheating et humilis spundering efficientiam. DC Magnettron spundly depositione ratio introducit magnetica agro. Magna ager generans generat fortis magnetica agro terga scopum. Haec magnetica agri interacts cum electrica agro ligare electrons juxta scopum superficiem, formatam summus density plasma regionem. His electrons praestare spiralis motus in magnetica agro, augendae frequentiam de collisionum cum operantes Gas moleculis, melecuting ad ionization efficientiam et spundering rate.

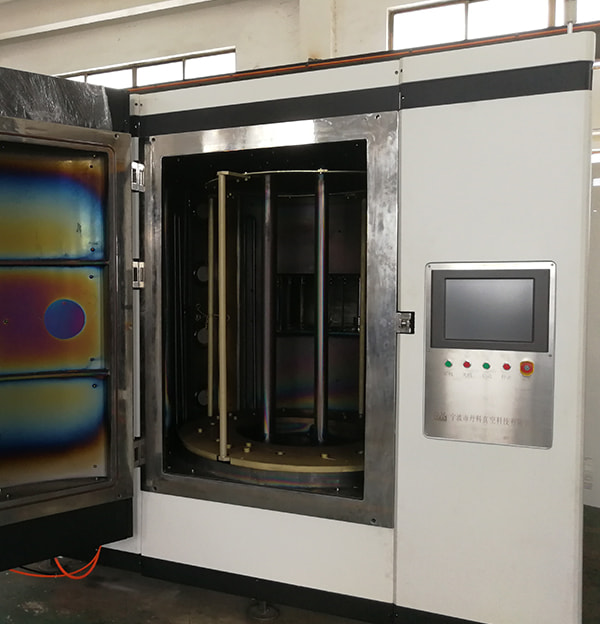

Ratio summary

Multi arcus Ion & spundly coatings potest deposita in lateque colorum. Et sonuit de coloribus potest esse adhuc auctus per introducendis reactivum vapores in camera per depositionem processus. Et late usus reactive vapores ad ornamentum coatings sunt NITROGENIUM, oxygeni, argon aut acetylene. Et exornantur coatings producuntur in quadam color range, fretus in metallum, ut-Gas Ratio in coating et structuram de coating. Et horum factores potest mutantur mutantur depositionem parametri.

Prior depositionem, partes purgari et superficies est liberum pulvis vel eget impudicitiis. Cum autem coating processus habet coepi, omnes pertinet processus parametri continue monitored et imperium per automatic computatrum imperium ratio.

• Substratum material: speculum, metallum (ipsum ferro, immaculatam ferro, aes): Ceramics, plastic, jewelry.

• structura type: vertical structuram, # CCCIV immaculatam ferro.

• coating film: multi-muneris metallum film, compositum amet, transparent PROMMIX film, reflectance-augendae amet, electro tutum film, exornantur amet.

• Film color: multi colore, gun nigrum, Titanium aureum color, Rose aureum color, immaculatam ferro color, purpura color, tenebris nigrum, tenebris hyacintho et alia colorum.

• Film Type: Stagni, CRN, ZRN, TICN, TICRN, tinc, tialn et DLC.

• Consumables in productio: Titanium, Chromium, Zirconium, ferrum, mixturae scopum; Planum scopum, cylindricus scopum geminae scopum oppositum scopum.

Application:

• Glassware, ut speculum calicem, speculum lucernas, speculum artworks.

• plastic phone testa, phone partes.

• Mosaic Tile.

• Electron industria, ut emi film.

• Vigilo partes, sicut vigilia causa et balteum.

• Table wares, sicut metallum fertur et cultris.

• Golf Wares, sicut Satis caput, Satis poli et golf balls.

• sanitary products / balneo wares.

• Porta handles & comas.

• Metal Jewelry.

Email:

Email:  Tel:+ 86-13486478562

Tel:+ 86-13486478562

LENTITUDO

LENTITUDO

Tel: + 86-13486478562

Tel: + 86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina

Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina