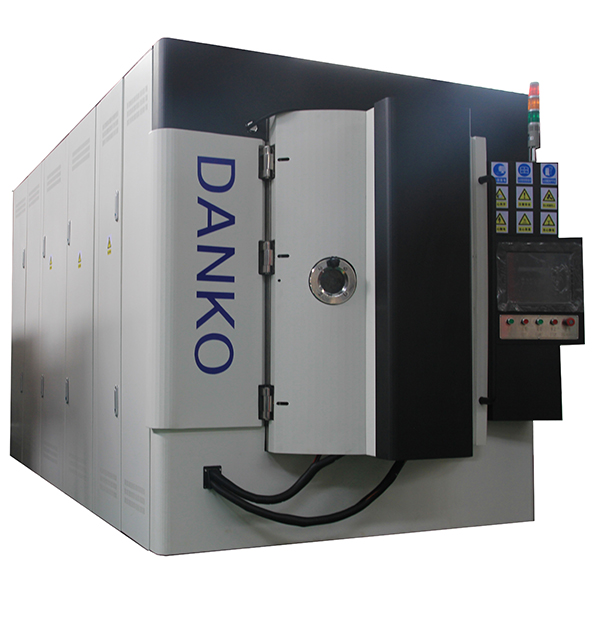

High-End Products PVD Vacuum Coating Machine needs to carry out a series of preparations before starting work, check whether the key components of the equipment such as the vacuum system, heating system, and control system are operating normally, ensure that the equipment is in the condition, place the workpiece to be coated in the vacuum chamber, and ensure that the surface of the workpiece is clean, free of oil and impurities. Post praeparationem perficitur apparatu incipit decedere. Per actionem vacuum sentinam, in aere in vacuo thalamum est paulatim extraxit usque ad praefinitum vacuo gradu est pervenit. Cum vacuo gradu pervenit ad postulationem, in apparatu incipit ad calefacere metallum aut mixturae scopum. In scopum calefacta ad evaporatio temperatus per electronicam trabem, resistentia seu inductionem calefacit. Per calefacit processus, atomis super superficiem scopum lucrum satis industria evadere et formam metallum vapor. In metallum vapor diffundit libere in vacuo environment et traducitur ad superficiem in workpiece. Per transmissionem processus, in vapor moleculis ut collidetur cum RELICTUM Gas moleculis in vacuo cubiculum, sed ex excelsis vacuo gradu, impulsum hoc collisione in vapor est neglegenda. Cum vapor moleculis pervenire superficiem workpiece, condense super superficiem et formare coating. Hoc processus vocatur vapor depositione. Post coating perficitur, apparatu subire refrigerationem processum ut coating potest pervenire firmum statum ante remotum. Postquam coating refrigerare, vacuum camera aperi potest et iactaret workpiece potest. In hoc puncto, in superficies workpiece est operuit cum uniformis et densa metallum aut mixturis film cum perficiendi.

Ratio summary

Multi arcus Ion & spundly coatings potest deposita in lateque colorum. Et sonuit de coloribus potest esse adhuc auctus per introducendis reactivum vapores in camera per depositionem processus. Et late usus reactive vapores ad ornamentum coatings sunt NITROGENIUM, oxygeni, argon aut acetylene. Et exornantur coatings producuntur in quadam color range, fretus in metallum, ut-Gas Ratio in coating et structuram de coating. Et horum factores potest mutantur mutantur depositionem parametri.

Prior depositionem, partes purgari et superficies est liberum pulvis vel eget impudicitiis. Cum autem coating processus habet coepi, omnes pertinet processus parametri continue monitored et imperium per automatic computatrum imperium ratio.

• Substratum material: speculum, metallum (ipsum ferro, immaculatam ferro, aes): Ceramics, plastic, jewelry.

• structura type: vertical structuram, # CCCIV immaculatam ferro.

• coating film: multi-muneris metallum film, compositum amet, transparent PROMMIX film, reflectance-augendae amet, electro tutum film, exornantur amet.

• Film color: multi colore, gun nigrum, Titanium aureum color, Rose aureum color, immaculatam ferro color, purpura color, tenebris nigrum, tenebris hyacintho et alia colorum.

• Film Type: Stagni, CRN, ZRN, TICN, TICRN, tinc, tialn et DLC.

• Consumables in productio: Titanium, Chromium, Zirconium, ferrum, mixturae scopum; Planum scopum, cylindricus scopum geminae scopum oppositum scopum.

Application:

• Glassware, ut speculum calicem, speculum lucernas, speculum artworks.

• plastic phone testa, phone partes.

• Mosaic Tile.

• Electron industria, ut emi film.

• Vigilo partes, sicut vigilia causa et balteum.

• Table wares, sicut metallum fertur et cultris.

• Golf Wares, sicut Satis caput, Satis poli et golf balls.

• sanitary products / balneo wares.

• Porta handles & comas.

• Metal Jewelry.

Email:

Email:  Tel:+ 86-13486478562

Tel:+ 86-13486478562

LENTITUDO

LENTITUDO

Tel: + 86-13486478562

Tel: + 86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina

Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina