1. effectus in coating Adhesio Electio materialis clypei locum criticum agit in adhaesione tunicae subiectae depositae. Adhaesio pendet a c...

Read MoreNingbo Danko Vacuum Technology Co., Ltd. Cum MMXX

Ningbo Danko Vacuum Technology Co., Ltd. Est committed ad expanding nostra foro terminis providente summus qualitas, summus perficientur vacuum coating apparatu. Noster turma valde focused in post-venditionesque servitium in domesticis et internationalis fora, providente accurate pars dispensando consilia et professional solutions in occursum customers 'necessitates.

-

-

Provectus Motus Imperium and Multi-Axis Positioning Summus perficientur Fingit machina coating gravis innititur motu progressivo s...

Read More -

Cathode Design and Target Erosion Management The Multi arcus Ion Coating Machina scutorum cathode multiplex nititur ad genera...

Read More -

Vacuum et Impetus Salutis Decorative Vacuum Coating Machines agunt sub condiciones vacuos altae vel ultra-alta...

Read More

Providebit specifica applicationem exempla de scelerisque evaporation Magnetron ludicris coating machinis

Hic sunt quaedam specifica applicationem exempla scelerisque evaporatio et Magnettron spundly coating machinis Danko vacuum Technology providit a Ningbo Danko, Ltd.:

Thermal evaporatio coating Applications: Optical coatings: scelerisque evaporatio est late propter depositis anti-reflective et reflective coatings in optical components sicut lentium, specula et specula. Haec coatings augendae optical perficientur per reducendo fulgor et meliorem lucem traductionem.

Thin Film Electronics: This method is utilized in the production of thin film transistors and sensors, particularly in displays and photovoltaic cells, where precise control over layer thickness is critical.Decorative Coatings: Thermal evaporation is effective for applying decorative metallic finishes on consumer goods, jewelry, and automotive parts, providing a visually appealing appearance while adding a layer of protection.

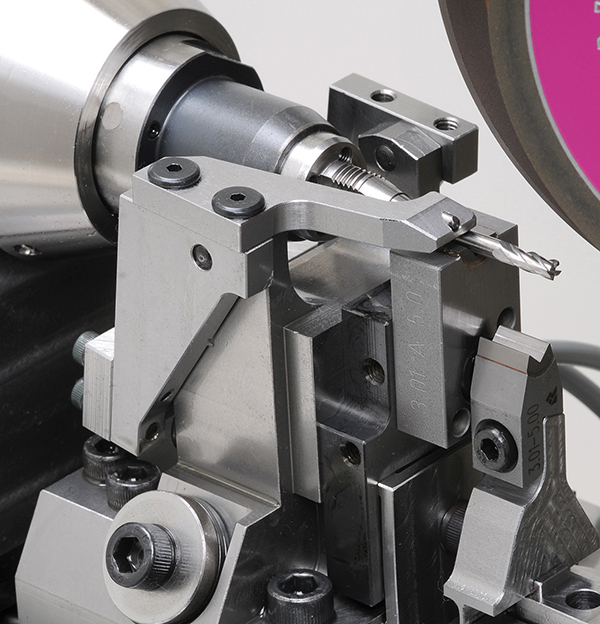

Barrier Films: Used in packaging applications, thermal evaporation creates thin barrier coatings that protect products from moisture and oxygen, extending shelf life and maintaining quality.Magnetron Sputtering Coating Applications:Hard Coatings for Tools: Magnetron sputtering is commonly used to deposit hard coatings, such as TiN (Titanium Nitride) and CrN (Chromium Nitride), on cutting tools and Industrial machinery. Haec coatings augendae gerunt resistentia extend tool vitae.

Semiconductor vestibulum, in Semiconductor fabricae, Magnetron pulterturi adhibetur pro depositis tenuis films de metallis et dielectrics, discrimine in integrated cellulis et microelectrons, in quo cidmium telluride (Cds of Materials Telluride (C.) aut CIGS Telluride Gale (cigs) vel CIGS Selenide Sunt crucial ad industria conversionem efficientiam.

Decorative et eget coatings: Magnettron spundly est etiam propter applicationem exornantur et eget coatings in Books, Architecturae components, et Consumer Electronics, similes ad excelsum, et speculis, offering superioris et adhaesionem.

Hae application exempla illustrent versatility et efficaciam de utroque scelerisque evaporatio et Magnettron spundly coating technologiae per varia industries, inter Optica, electronics, automotive, et fabricatur, et manufacturing.

Email:

Email:  Tel:+ 86-13486478562

Tel:+ 86-13486478562

LENTITUDO

LENTITUDO

Tel: + 86-13486478562

Tel: + 86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina

Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina