1. effectus in coating Adhesio Electio materialis clypei locum criticum agit in adhaesione tunicae subiectae depositae. Adhaesio pendet a c...

Read MoreNingbo Danko Vacuum Technology Co., Ltd. Cum MMXX

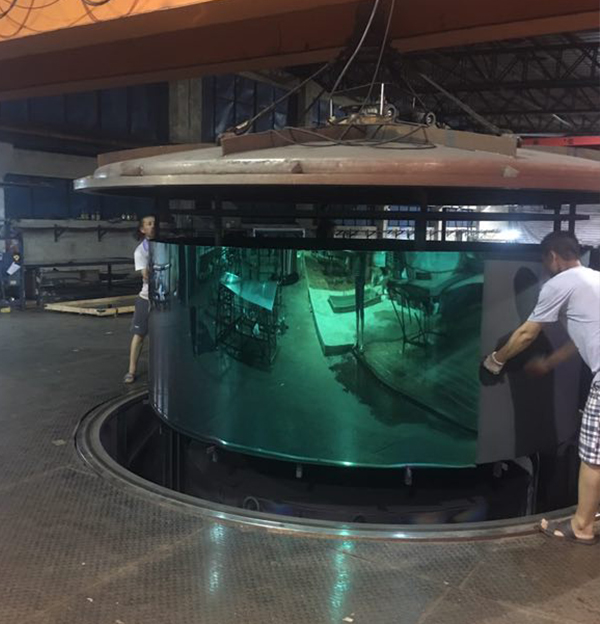

Ningbo Danko Vacuum Technology Co., Ltd. Est committed ad expanding nostra foro terminis providente summus qualitas, summus perficientur vacuum coating apparatu. Noster turma valde focused in post-venditionesque servitium in domesticis et internationalis fora, providente accurate pars dispensando consilia et professional solutions in occursum customers 'necessitates.

-

-

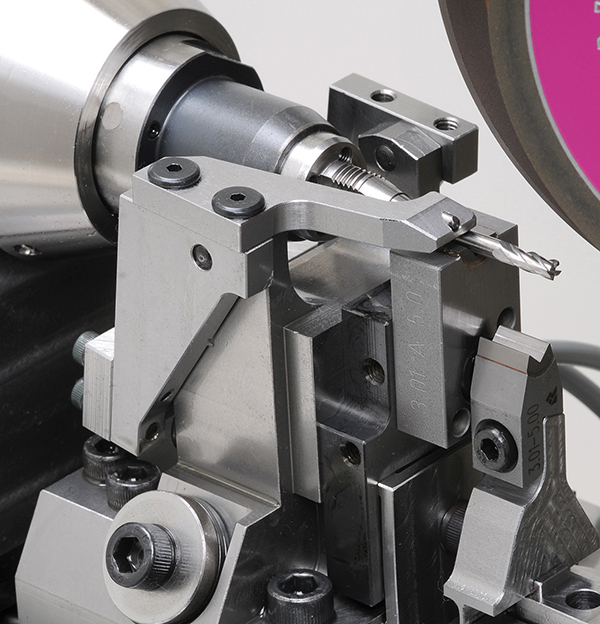

Provectus Motus Imperium and Multi-Axis Positioning Summus perficientur Fingit machina coating gravis innititur motu progressivo s...

Read More -

Cathode Design and Target Erosion Management The Multi arcus Ion Coating Machina scutorum cathode multiplex nititur ad genera...

Read More -

Vacuum et Impetus Salutis Decorative Vacuum Coating Machines agunt sub condiciones vacuos altae vel ultra-alta...

Read More

Magna ferro et supellectilem coating machinis ut mensuras ad redigendum impulsum in environment in coating processus

Magna ferro et supellectilem coating machinis Potest capere a varietate strategies ad significantly reducere eorum environmental ictum per coating processus, focusing in sustineri, resource efficientiam et pollutio reductionem. Hic sunt quaedam detailed mensuras:

Minimum-voc et Eco-amica coatings: per usura coatings cum humilis volatile organicum componit (vocs), manufacturers potest minimize remissionis de nocivis emissiones per applicationem processus. Hoc non solum amplio aeris qualis sed etiam adjuvat in obsequio cum environmental ordinationes. Eco-amica coatings, ut illa fundatur in bio-fundatur materiae, potest ultra redigendum environmental harm.closed-loop systems: effectum effectum clausa-loop systems pro solvente convaluisset, et redivivus et redivivus materiae. Hoc reduces vastum per permittens solvents et aliis materiae ad esse ressum in coating processus, ita obscuratis opus novum opibus et minuantur productio costs.

Energy Efficens: Machinarum disposito cum industria efficientiam in mente potest ducere ad significant reductiones in industria consummatio. Features ut summus efficientiam Motors, DUXERIT luctu et optimized calefactio systems auxilium diminutionem altiore industria demanda de coating processus. Praeterea, utilizing renovabili industria fontes, ut solaris vel vento potentia, potest adhuc augendae sustainability.water, secundum coatings: transitioning ad aqua-secundum coatings pro traditional solvironmental, secundum options potest valde minuere, fundatur options potest valde minuere-fundatur options potest valde minuere, secundum options potest vehementer in modum solvitonmental impulsum. Aqua-fundatur formities typice continent paucioribus nocivis chemicals et solvents, unde in inferioribus emissiones et tutius working environment.

Advanced Filtration Systems: Incorporating Sophisticated Filtration Systems potest capere aerium particulas, overspray et aliis emissiones in coating processus. Hi systems auxilium ut pollutants sunt neutralized ante intrant atmosphaera, ita maintaining a lautus environment et domesticas et outdoors.efective vastum procuratio exercitia: constituendum robusti environmental ictum. Hoc includit redivivus Scrap materiae, bene administrandi ancipitia vastum, et cursus ut omnes per-products de coating processus sunt tractantur in environmentally responsible modo.

Eco-friendly coating processus: usus ECO, amica processibus sicut pulveris coating potest significantly reducere environmental ictum. Pulveris coating utitur non solvents et emittit virtualiter nulla volatile organicum componit, faciens illud lautus alternative quod etiam offert optimum diuturnitatem et finiantur, tempus vigilantia systems sino pro precise potestatem et minimize desertum. Monitoring variables ut temperatus, pressura et applicationem rates, manufacturers potest cito adjust res ad augendae efficientiam.

Operator disciplina et conscientia: providente comprehensive disciplina ad operators in environmentally reus est essentialis. This includes educating them about the importance of minimizing waste, using materials efficiently, and adhering to safety and environmental standards.Regulatory Compliance: Ensuring compliance with local and international environmental regulations is crucial for sustainable operations. Hoc non modo adjuvat vitare legalis poenarum sed etiam confirmat a commitment ad responsible vestibulum exercitia.

Sustainable Supply catena exercitia: Services cum Suppliers qui prioritize sustineri potest adhuc augendae environmental nisus. Hoc potest includere Fontes rudis materiae ex Sustainable fontes, ensuring quod amet sequitur environmentally amica exercitia, et opting ad loci amet ad redigendum translationem emissiones.

Per adoptando haec, magna ferro et supellectilem coating machinarum potest significantly minuere sua environmental vestigium dum etiam meliorem operational efficientiam et enhancing uber qualitas. Hoc commitment ad sustineri potest etiam positive influere notam fama et Lorem fide in per increasingly Eco-conscious Market.

Email:

Email:  Tel:+ 86-13486478562

Tel:+ 86-13486478562

LENTITUDO

LENTITUDO

Tel: + 86-13486478562

Tel: + 86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina

Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina