Vacuum Environment The vacuum machinam coating operatur in ambitu humili pressurae, quae una est e...

Read MoreNingbo Danko Vacuum Technology Co., Ltd. Cum MMXX

Ningbo Danko Vacuum Technology Co., Ltd. Est committed ad expanding nostra foro terminis providente summus qualitas, summus perficientur vacuum coating apparatu. Noster turma valde focused in post-venditionesque servitium in domesticis et internationalis fora, providente accurate pars dispensando consilia et professional solutions in occursum customers 'necessitates.

-

-

1. effectus in coating Adhesio Electio materialis clypei locum criticum agit in adhaesione tunicae subiectae depositae. Adhaesio pendet a c...

Read More -

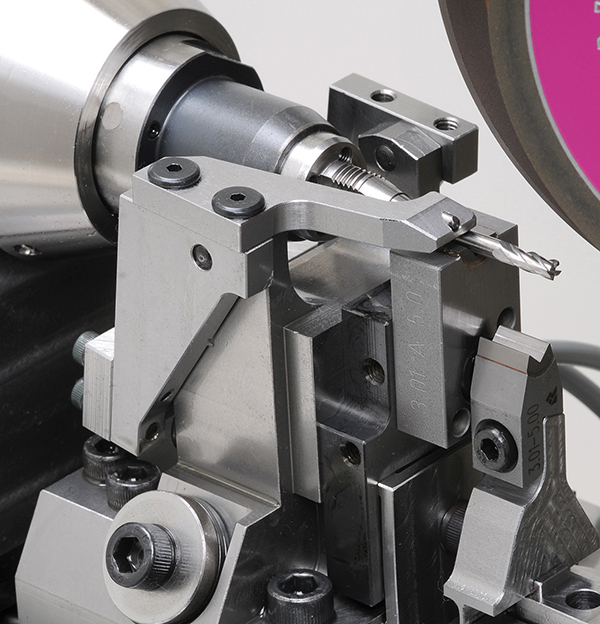

Provectus Motus Imperium and Multi-Axis Positioning Summus perficientur Fingit machina coating gravis innititur motu progressivo s...

Read More -

Cathode Design and Target Erosion Management The Multi arcus Ion Coating Machina scutorum cathode multiplex nititur ad genera...

Read More

Imprimis coating technology usus est a comitatu scriptor automotive Trim coating machinis

Ningbo Danko vacuo Technology Co., Ltd. Utilitas varietate provectus coating technologiae in Automotive Trim coating machinis , Quisque tailored ad consequi specifica perficientur et aesthetic qualitates. Hic est altius dive in his technologiae:

Physica vapor depositione (PVD) PVD est angularis technology pro automotive Trim coatings, offering superior adhaesionem et lateque de color options. Processus incipit in vacuo cubiculum ubi solidum materiae sunt vaporized per scelerisque calefacit et sputhting. Vapor et condensibus onto superficies of automotive Trim, formatam tenuis, durabile coating. Hoc modum est notum ad suum facultatem ad producendum coatings, quae non solum uisum appellans sed etiam repugnant ad scalpit et gerunt.

Spulgating: in spundering processus, summus industria ions bombard a scopum materia, ejiciendo atomos qui tunc deposita onto in automotive Trim. Hoc ars concedit pro fine imperium in coating scriptor crassitiem et compositionem, enabling artifices ad creare stratis cum proprietatibus specifica, ut melius reflectivity aut auctus color altitudinem. Saepe exhibeant excellented et cooperantur cooperantur, faciens ea specimen complexu figuras in automotive Criminibus.

Thermal evaporatio: hoc modo involvit calefactio materiae usque ad evanescere in vacuo environment. Vapor et iter ad subiectum, ubi condenses ad formare coating. Effective effective vacat et uniformis coatings uniformis scelerisque est maxime efficaciter, quod idoneam applications ubi aesthetic qualis est paramaunt. Potest adhiberi ad partum a varietate finit, ex altus-Glossa ad matte.

Multi Arcus Ion plating: multi, arcus Ion plating auget depositione processus per plures arces ad creare plasma in vacuo cubiculum. Hoc summus industria environment accelerat depositionem rate et amplio qualis est coating. Et effectus est densa, durum coating quod praebet optimum resistentia ad induendum et corrosio, faciens illud bene apta automotive applications patere dura conditionibus.

Chemical vapor depositione (CVD): Dum minus commune in exornantur applications, cvd potest adhibere ad specifica automotive Trim coacta requiring unique proprietatibus. Hoc ars involves eget reactiones quae fieri in Gas tempus, ducens ad depositionem de solidum materia in subiecto. CVD potest producere coatings cum praeclara scelerisque stabilitatem et eget resistentia, faciens apta specialized automotive components.

Roll-to-volumine coating: nam fabrica commercio cum flexibile Automotive Trim elementa, volumine-ut-volumine coating offert continua productio processus, quod potest significantly augendae efficientiam. Hoc modum concedit pro celeri coating magnarum rotulis de materia, faciens idealis pro summus volumen applications. Etiam ope manufacturers ad consequi consistent coating qualitas per extensive superficiebus.

Laser ablationem et superficiem curatio: praeter traditional coating modi, quidam fabrica ut incorporant laser techniques parare superficiebus aut modify existentium coatings. Laser ablationem potest augendae adhaesionem a partum Micro-textured superficiebus, dum superficiem curatio potest amplio diuturnitatem et perficientur de coatings.

Per haec diverse coating technologiae, Ningbo Danko vacuo Technology Co., Ltd ensures quod eorum automotive Trim coatings non solum occursum aesthetic postulat sed etiam providere in functionality requiritur in automotive industria et functionality requiritur in auctam. His provectis coatings potest resistere environmental passiones resistere scalpit et abrasions, et aspectus eorum in tempore, ultimately enhancing altiore qualis appellatio automotive interiors.

Email:

Email:  Tel:+ 86-13486478562

Tel:+ 86-13486478562

LENTITUDO

LENTITUDO

Tel: + 86-13486478562

Tel: + 86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina

Address: No. LXXIX Occidentem jinniu via, Yuyao, Ningbo City, Zhejiang Provice, Sina